SECTION 5 - HAND KNOBS

WDS

&

0845 606 66 77

•

:

www.wdsltd.co.uk•

*

sales@wdsltd.co.uk5-16

WDS

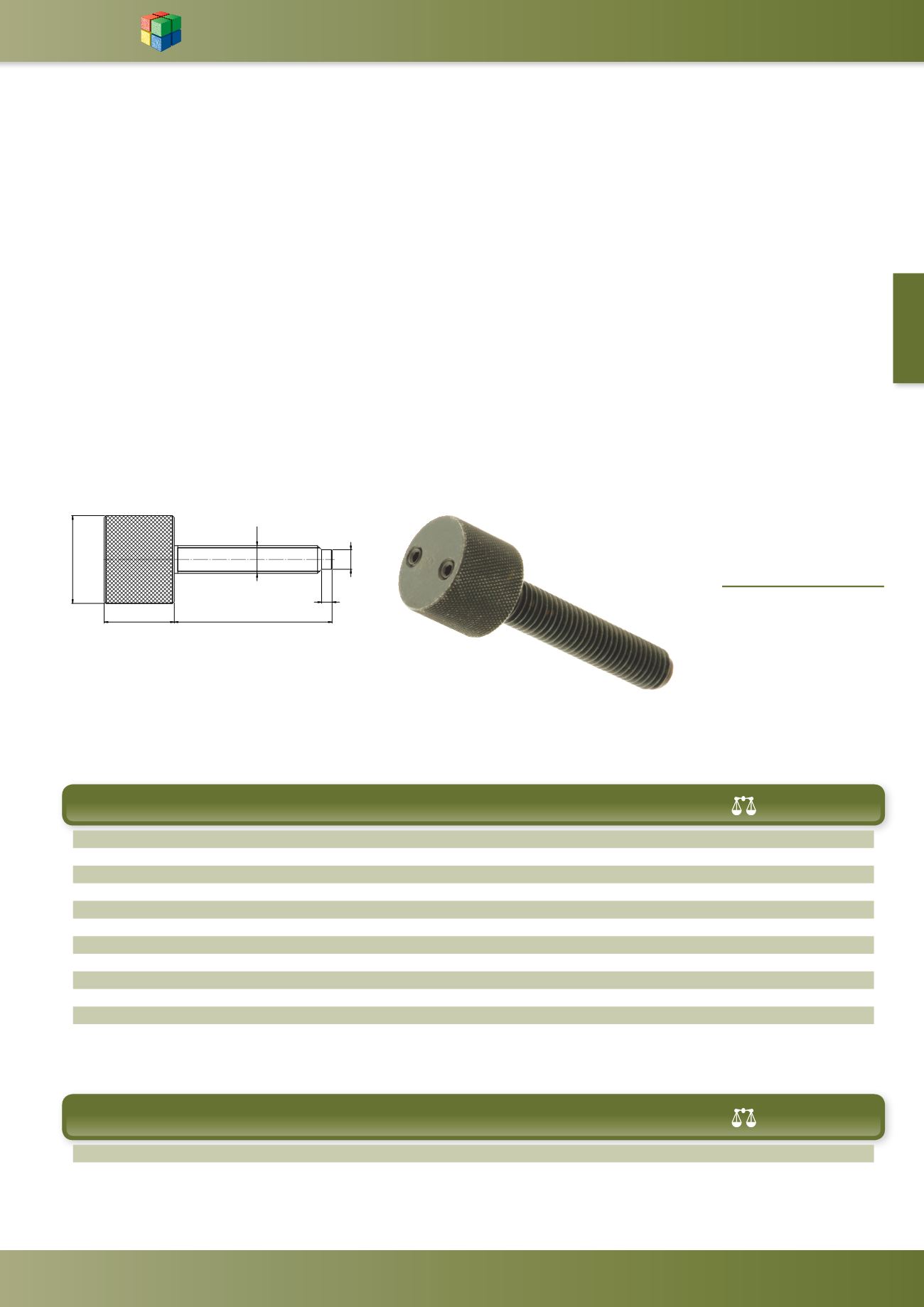

www.wdsltd.co.ukTorque Screw

WDS 700

MATERIAL

-

Head - Steel

BS.970 Gr.220M07

Screw - Steel

BS.970 Gr.212A42

Chemical Black Finish

Torque Screws and Knobs Section

Torque applied to the knurled knob is transmitted to the driving plate of the screw by means of two spring loaded

balls in conical seatings, thereby tightening the screw. Dependent upon the spring loading, the balls will be forced up

the inclined sides of the dimples until they reach the flat surface of the driving plate. Slippage will then occur and no

further increase in the clamping load of the screw is possible. To unclamp, the screw is turned in an anti clockwise

direction.

Should the clamping load be too great, then this can be reduced by adjusting the spring pressure on the balls.

Slackening of the grub screws will reduce the load exerted by the springs. To increase the clamping load of the screw,

the grub screws should be tightened. Care should be taken not to screw them too far otherwise the balls will become

locked solid in the seatings and the torque action become non-operative. Adjustments should only be carried out

whilst the screw is in a non-working situation. The whole assembly is retained by means of a circlip.

Once the required clamping load by the screw has been achieved, it will be repeated to a reasonable tolerance on

successive components.

F1 = Minimum end pressure (kg)

F2 = Maximum end pressure (kg)

D

L

D1

D2

H

E

F1

F2

(g)

WDS No.

M6

40

25

4.5

20

3

4

80

75

700-201

M6

60

25

4.5

20

3

4

80

77

700-202

M8

40

25

6.0

20

3

4

65

80

700-203

M8

60

25

6.0

20

3

4

65

85

700-204

M8

80

25

6.0

20

3

4

65

90

700-205

M10

40

25

7.8

20

3

4

55

95

700-206

M10

60

25

7.8

20

3

4

55

105

700-207

M10

80

25

7.8

20

3

4

55

110

700-208

M12

40

25

9.4

20

3

4

45

100

700-209

M12

60

25

9.4

20

3

4

45

115

700-210

M12

80

25

9.4

20

3

4

45

125

700-211

M12

100

25

9.4

20

3

4

45

140

700-212

Metric

D

L

D1

D2

H

E

F1

F2

(g)

WDS No.

UNC

1

⁄

4

45

25

4.4

20

3

4

80

80

700-45

5

⁄

16

45

25

5.6

20

3

4

60

85

700-47

Inch

'

'

(

/

+

'

) 0LQLPXP HQG SUHVVXUH NJ

) 0D[LPXP HQG SUHVVXUH NJ