SECTION 2 - LOCATION & POSITIONING

WDS

WDS

www.wdsltd.co.uk2-49

&

0845 606 66 77

•

:

www.wdsltd.co.uk•

*

sales@wdsltd.co.uk/

'

'

+

'

.185/

3 ,QLWLDO 6SULQJ 3UHVVXUH NJI

3 )LQDO 6SULQJ 3UHVVXUH NJI

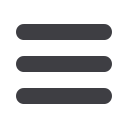

Double Ended

Spring Plunger

WDS 618

MATERIAL

-

Body: Brass

Spring: Stainless Steel

Ball: Stainless Steel Hardened

Maximum durable temp is 180°C

D

D1

D2

L

H

P1

P2

(g)

WDS No.

2.5

2

2.55

10

0.65

0.15

0.27

0.5

618-201

3

2.5

3.05

8

0.8

0.25

0.59

0.6

618-202

4

3

4.05

10

0.9

0.29

0.69

0.7

618-203

5

4

5.05

12

1.2

0.39

0.78

1.3

618-204

6

5

6.05

16

1.6

0.59

0.98

2.4

618-205

8

6

8.05

20

2

0.78

1.18

5.8

618-206

10

8

10.05

24

2.9

0.98

1.57

10.5

618-207

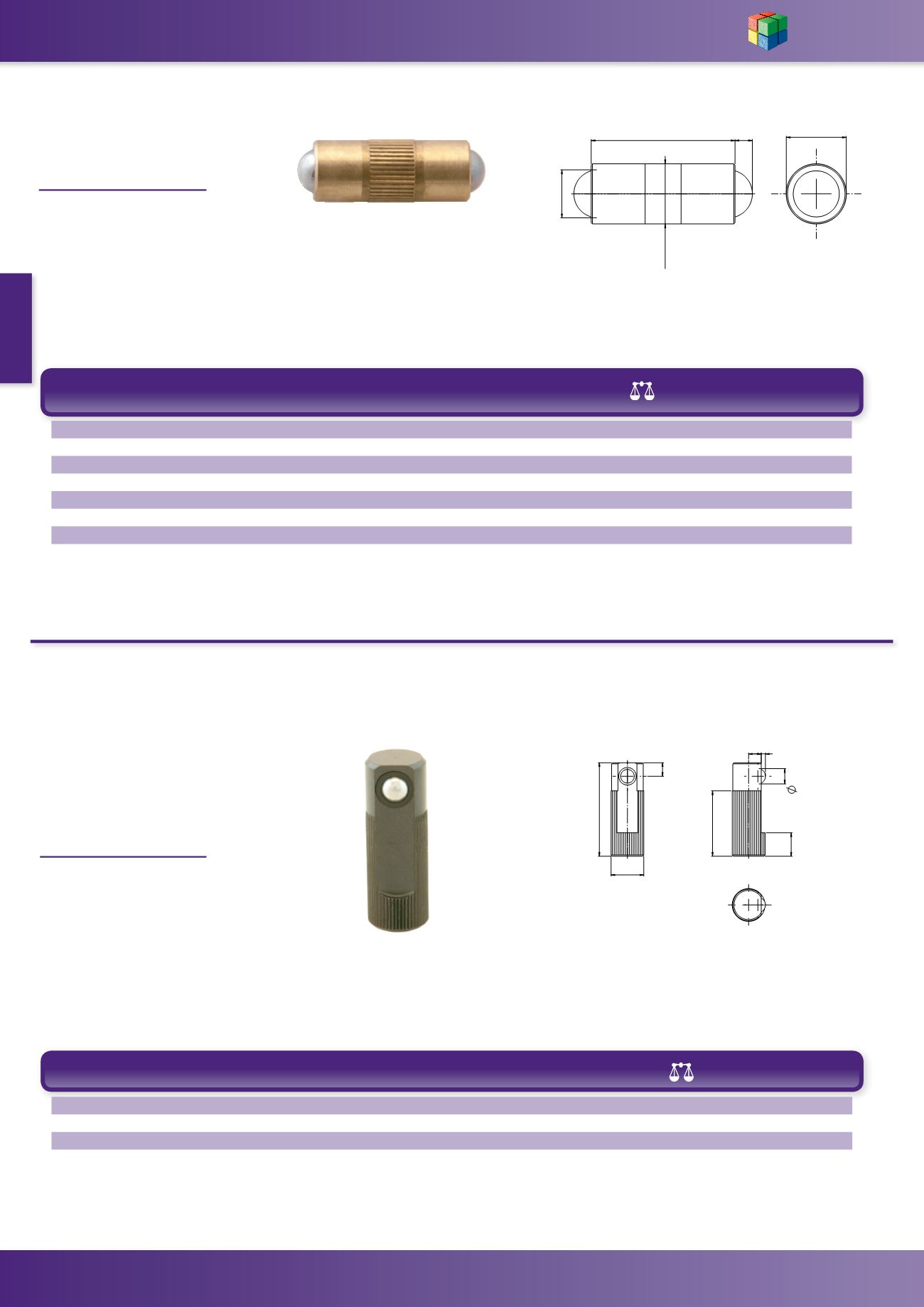

Lateral Ball

Spring Plunger -

Stainless Ball

WDS 608

MATERIAL

-

Body - Mild Steel - Chemical

black

Ball - 303 Stainless Steel

Spring- 303 Stainless Steel

E

A

D2

BALL

B

F

KNURL

L

D

C

P1 = Initial spring force (kgf)

P2 = Final spring force (kgf)

H = Hole dia required for fitting

Lateral spring plunger should be inserted to depth 'E' minimum

D D1

L

A

B

C

E

F

H P1

P2

(g)

WDS No.

8

3

25 3.2 0.7 3.6

6 16.9 8 H8 0.26 0.66

9

608-108

10

4

30

4

1

4.2

7 20.8 10 H8 0.46 0.92

17

608-110

12

5

35

5

1.5 4.8

9 24.7 12 H8 0.66 1.33

29

608-112

14 6.5 40 5.4 1.8 5.8 10 28.0 14 H8 0.82 1.84

43

608-114