SECTION 2 - LOCATION & POSITIONING

WDS

&

0845 606 66 77

•

:

www.wdsltd.co.uk•

*

sales@wdsltd.co.uk2-50

WDS

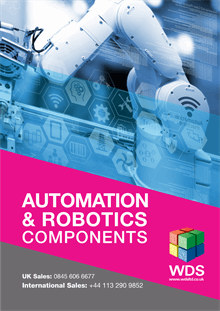

www.wdsltd.co.ukDouble Lateral

Spring Plungers -

Steel Ball Plastic

Spring

WDS 608

MATERIAL

-

Body - Mild Steel - Chemical

black

Ball - Hardened Steel

Spring - Plastic

E

A

D2

BALL

F

KNURL

B

B

L

D

C

P1 = Initial spring force (kgf)

P2 = Final spring force (kgf)

H = Hole dia required for fitting

Lateral spring plunger should be inserted to depth 'E' minimum

D D1

L

A

B

C

E

F

H P1

P2

(g)

WDS No.

16 5.5 35

15 1.5

7

11 22.3 16 H8 11.22 22.43

20

608-416

18 6.5 40

17 1.8

8

12 25.8 18 H8 12.24 33.65

27

608-418

22

8

45

21 2.5

9

15 29.0 22 H8 13.26 55.06

43

608-422

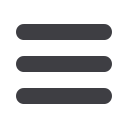

Lateral Spring

Plungers - Steel

Ball Plastic

Spring

WDS 608

MATERIAL

-

Body - Mild Steel - Chemical

black

Ball - Hardened Steel

Spring - Plastic

E

A

D2

BALL

B

F

KNURL

L

D

C

P1 = Initial spring force (kgf)

P2 = Final spring force (kgf)

H = Hole dia required for fitting

Lateral spring plunger should be inserted to depth 'E' minimum

D D1

L

A

B

C

E

F

H P1

P2

(g)

WDS No.

10 5.5 30 4.5

1

7

8 17.3 10 H8 6.12 17.34

9

608-310

12 6.5 35 5.5 1.5

8

9 20.8 12 H8 8.16 26.51

13

608-312

14

8

40 6.5

2

9

10 24.0 14 H8 12.24 48.95

19

608-314

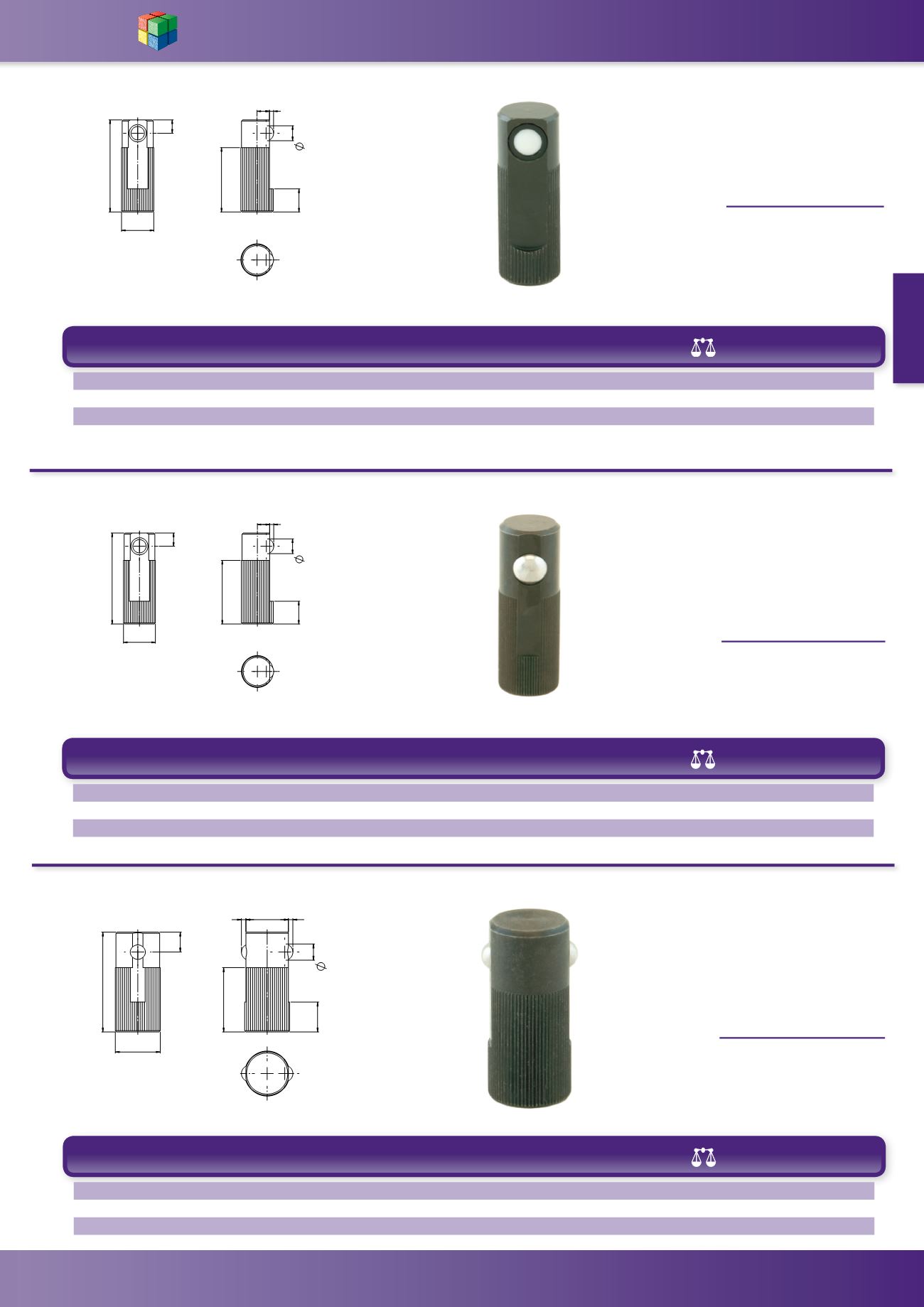

Lateral Ball

Spring Plunger -

Plastic Ball

WDS 608

MATERIAL

-

Body - Mild Steel - Chemical

black

Ball - Delrin

E

A

D2

BALL

B

F

KNURL

L

D

C

P1 = Initial spring force (kgf)

P2 = Final spring force (kgf)

H = Hole dia required for fitting

Lateral spring plunger should be inserted to depth 'E' minimum

D D1

L

A

B

C

E

F

H P1

P2

(g)

WDS No.

8

3

25 3.2 0.7 3.6

6 16.9 8 H8 0.26 0.66

9

608-208

10

4

30

4

1

4.2

7 20.8 10 H8 0.46 0.92

17

608-210

12

5

35

5

1.5 4.8

9 24.7 12 H8 0.66 1.33

29

608-212

14 6.5 40 5.4 1.8 5.8 10 28.0 14 H8 0.82 1.84

43

608-214